Research

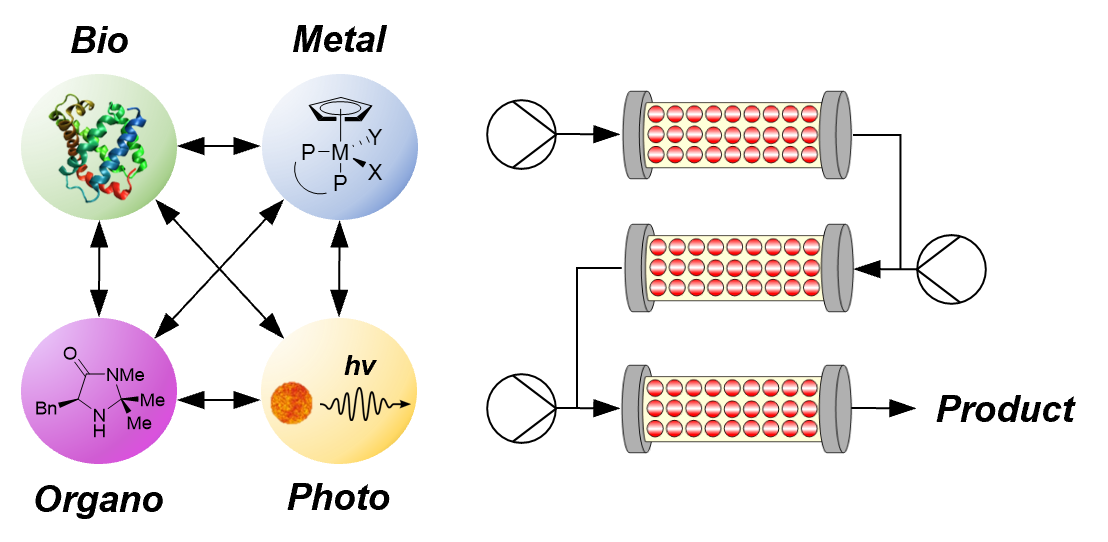

The group works at the interface of digital chemistry, machine learning and process engineering within the Institute of Process Research and Development at the University of Leeds. We are focused on advancing sustainable multistep synthesis of small molecules. Our interdisciplinary team develops and combines autonomous reactors and optimisation algorithms to explore a wide variety of multistep continuous flow processes. This approach combines advanced computational techniques with practical experimentation, enabling the seamless incorporation of digital methods into synthetic chemistry. We exploit these tools to primarily target the integration of different (photo-, bio-, chemo-) catalytic reactions into cascades, with the overall goal of reducing the carbon footprint of chemical manufacturing.

Digital Chemistry

Within the field of digital chemistry, we focus on developing and benchmarking new machine learning (ML) approaches to accelerate research and development and significantly reduce the time and resources required for chemical reaction optimisation. We leverage existing chemical data, and confront the challenge of data sparsity by generating new datasets using autonomous reactor platforms, ensuring our models are trained on comprehensive datasets that reflect real-world chemical behaviour. This enables us to efficiently and systematically explore vast experimental landscapes with high dimensional complexity, such as those observed in catalytic reactions and multistep processes. By utilising ML-guided experimentation, we aim to enhance our understanding of chemical systems and drive faster innovations in sustainable synthesis.

Selected Publications:

React. Chem. Eng. 2024, 9, 308

Chem. Sci. 2022, 13, 12087

Reaction Optimisation

Reaction optimisation is becoming increasingly critical for achieving efficient, sustainable syntheses, particularly as chemical industries prioritise greener, more resource-efficient processes. Our work focuses on integrating machine learning approaches with autonomous reactor platforms to create closed-loop systems capable of rapidly optimising chemical reactions. We employ multiobjective optimisation techniques that simultaneously consider economic and environmental objectives, enabling complex trade-offs to be characterised and exploited to achieve a balanced and responsible chemical process. To align with our interest in catalytic cascades, we also utilise mixed variable optimisation methods which are capable of simultaneously modelling continuous and categorical variables to capture key interactions and facilitate the rapid development of multistep syntheses.

Selected Publications:

Angew. Chem. Int. Ed. 2023, 62, e202214511

Chem. Eng. J. 2023, 451, 138443

Multistep Flow Synthesis

Multistep flow synthesis offers a powerful approach for creating small molecules on-demand and with a higher efficiency compared to traditional batch methods. We are particularly interested in the design and development of continuous processes that integrate different catalytic reactions into a single flow system, enabling a series of complex chemical transformations to be performed sustainably. By eliminating the need for intermediate isolations and purifications where possible, we aim to significantly reduce waste generated in chemical manufacturing. Our approach leverages advanced reactor design, online monitoring and holistic optimisation methods to address challenges in maintaining reaction stability and compatibility across sequential steps. Additionally, we explore modular reactor setups that can be easily reconfigured, enabling rapid adaptation to new synthetic targets.

Selected Publications:

ACS Sustainable Chem. Eng. 2024, 12, 15125

Chem. Eng. J. 2020, 384, 123340